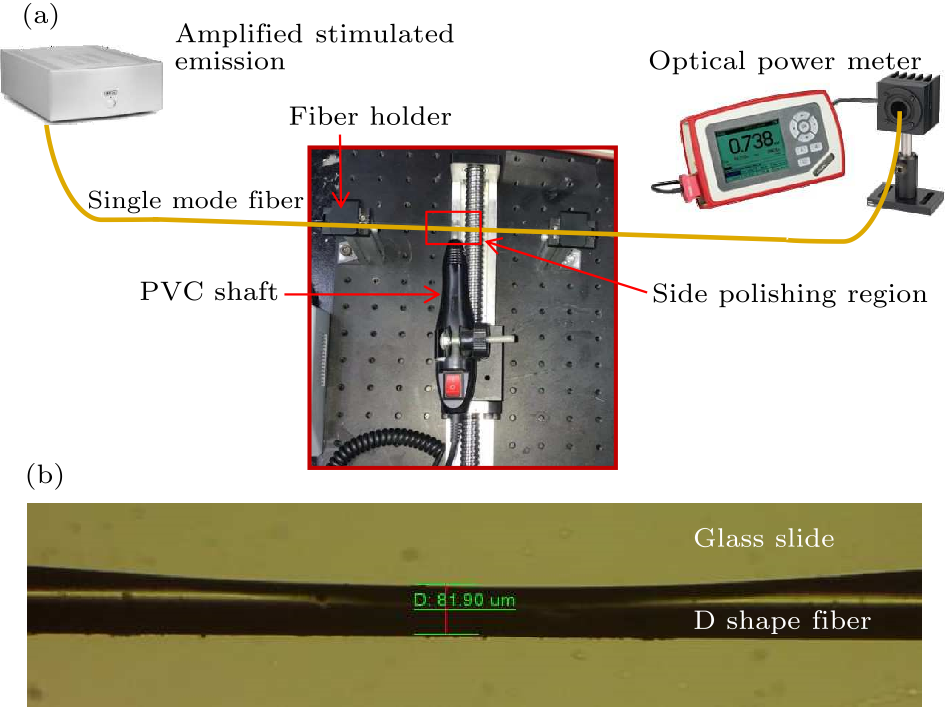

Fig. 1. (a) Fabrication setup of the D-shape fiber, and (b) the D-shape fiber.

Fig. 2. Electron beam deposition for ITO coating over D-shape region.

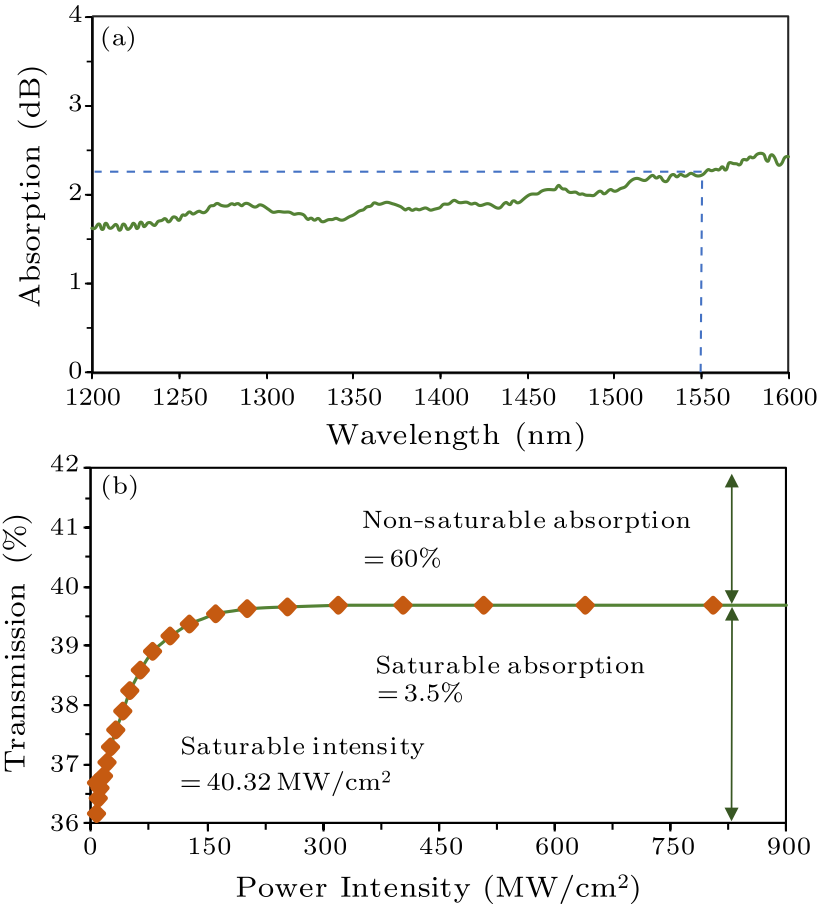

Fig. 3. Optical properties of ITO coated over the D-shape fiber: (a) linear absorption, (b) nonlinear absorption.

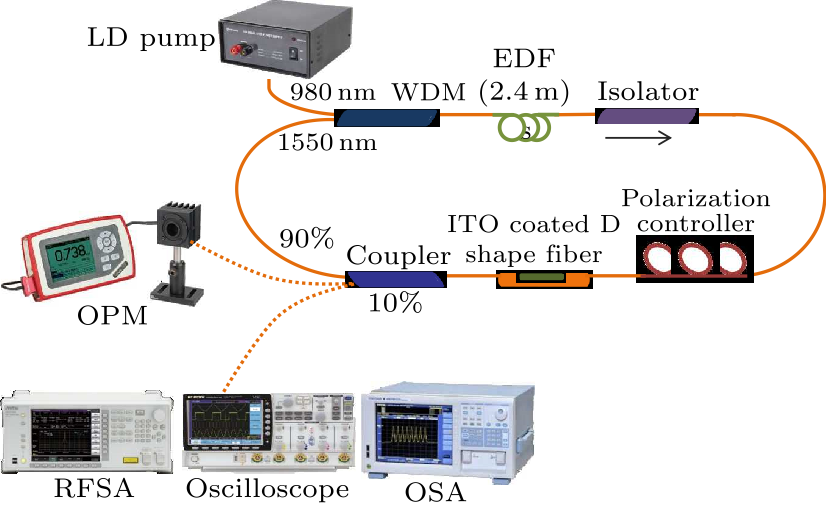

Fig. 4. EDFL ring cavity setup.

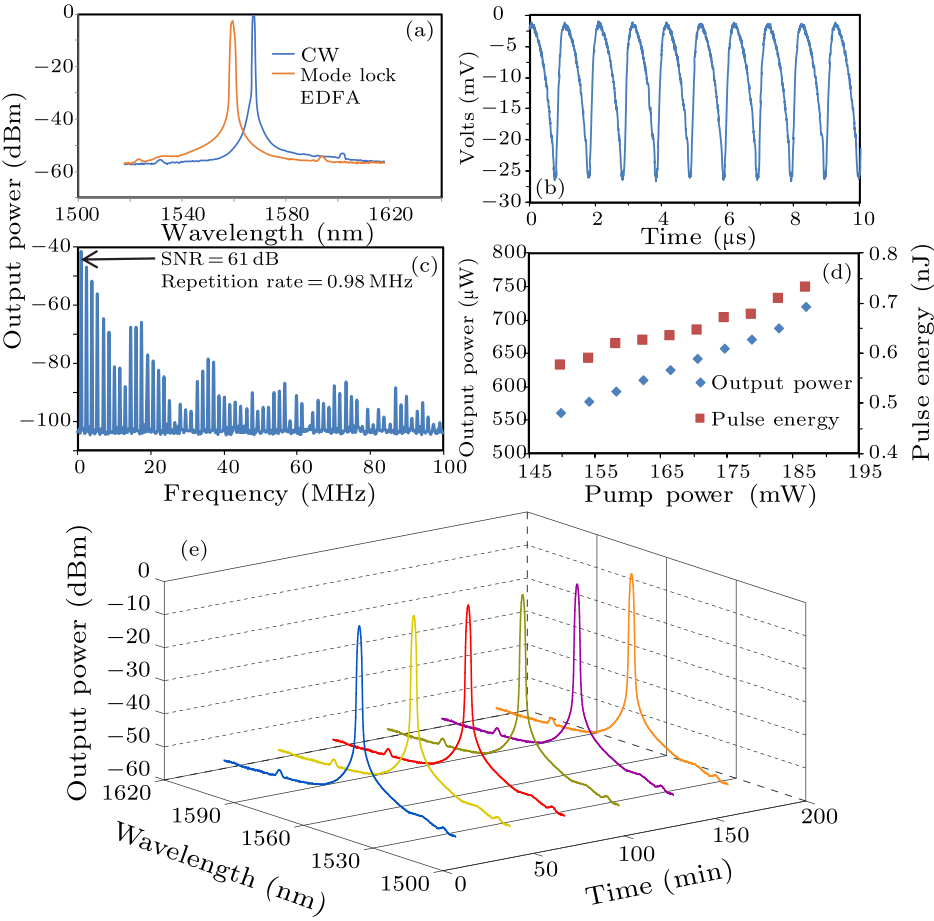

Fig. 5. Experimental results: (a) operating wavelength spectrum of continuous wave and mode locked, (b) oscilloscope trace ensuring dark pulse, (c) frequency spectrum, (d) output power and pulse energy against pump power, (e) mode locked laser stability for three hours.

| [1] | Keller U 2003 Nature 424 831 | Recent developments in compact ultrafast lasers

| [2] | Liu X et al 2015 Sci. Rep. 5 9101 | Distributed ultrafast fibre laser

| [3] | Sugioka K and Cheng Y 2014 Light: Sci. & Appl. 3 e149 | Ultrafast lasers—reliable tools for advanced materials processing

| [4] | Yan P et al 2015 Opt. Mater. Express 5 479 | Microfiber-based WS_2-film saturable absorber for ultra-fast photonics

| [5] | Sobon G et al 2012 Opt. Express 20 19463 | Graphene Oxide vs Reduced Graphene Oxide as saturable absorbers for Er-doped passively mode-locked fiber laser

| [6] | Salam S et al 2019 IET Optoelectron. 13 247 | Tris-(8-hydroxyquinoline) aluminium thin film as saturable absorber for passively Q-switched erbium-doped fibre laser

| [7] | Salam S et al 2019 Opt. Fiber Technol. 50 256 | FIrpic thin film as saturable absorber for passively Q-switched and mode-locked erbium-doped fiber laser

| [8] | Gomes L A, Orsila L, Jouhti T and Okhotnikov O G 2004 IEEE J. Sel. Top. Quantum Electron. 10 129 | Picosecond SESAM-Based Ytterbium Mode-Locked Fiber Lasers

| [9] | Keller U et al 1996 IEEE J. Sel. Top. Quantum Electron. 2 435 | Semiconductor saturable absorber mirrors (SESAM's) for femtosecond to nanosecond pulse generation in solid-state lasers

| [10] | Bao Q et al 2009 Adv. Funct. Mater. 19 3077 | Atomic-Layer Graphene as a Saturable Absorber for Ultrafast Pulsed Lasers

| [11] | Liu X et al 2013 Sci. Rep. 3 2718 | Versatile multi-wavelength ultrafast fiber laser mode-locked by carbon nanotubes

| [12] | Lau K et al 2018 Opt. Laser Technol. 102 240 | Low threshold linear cavity mode-locked fiber laser using microfiber-based carbon nanotube saturable absorber

| [13] | Yamashita S, Martinez A and Xu B 2014 Opt. Fiber Technol. 20 702 | Short pulse fiber lasers mode-locked by carbon nanotubes and graphene

| [14] | Yan P, Lin R, Ruan S, Liu A, Chen H, Zheng Y, Chen S, Guo C and Hu J 2015 Sci. Rep. 5 8690 | A practical topological insulator saturable absorber for mode-locked fiber laser

| [15] | Zhang H, Lu S, Zheng J, Du J, Wen S, Tang D and Loh K 2014 Opt. Express 22 7249 | Molybdenum disulfide (MoS_2) as a broadband saturable absorber for ultra-fast photonics

| [16] | Al-Masoodi A, Ahmed M, Latiff A, Arof H and Harun S W 2016 Chin. Phys. Lett. 33 054206 | Q-Switched Ytterbium-Doped Fiber Laser Using Black Phosphorus as Saturable Absorber

| [17] | Ahmad H, Reduan S, Aidit S and Tiu Z 2017 Chin. Opt. Lett. 15 020601 | Generation of passively Q-switched fiber laser at 1 μm by using MoSSe as a saturable absorber

| [18] | Duan L N, Su Y L, Wang Y G, Li L, Wang X and Wang Y S 2016 Chin. Phys. B 25 024206 | Passively mode-locked erbium-doped fiber laser via a D-shape-fiber-based MoS 2 saturable absorber with a very low nonsaturable loss

| [19] | Zhao W and Bourkoff E 1989 Opt. Lett. 14 703 | Propagation properties of dark solitons

| [20] | Li X, Zhang S, Meng Y and Hao Y 2013 Opt. Express 21 8409 | Harmonic mode locking counterparts of dark pulse and dark-bright pulse pairs

| [21] | Liu W, Pang L, Han H, Shen Z, Lei M, Teng H and Wei Z 2016 Photon. Res. 4 111 | Dark solitons in WS_2 erbium-doped fiber lasers

| [22] | Liu H and Chow K 2014 Opt. Express 22 29708 | Dark pulse generation in fiber lasers incorporating carbon nanotubes

| [23] | Wang T, Zhang W, Shi X, Wang J, Ding X, Zhang K, Peng J, Wu J and Zhou P 2019 Laser Phys. Lett. 16 085102 | Black phosphorus-enabled harmonic mode locking of dark pulses in a Yb-doped fiber laser

| [24] | Wang L 2013 Opt. Commun. 297 129 | Coexistence and evolution of bright pulses and dark solitons in a fiber laser

| [25] | Alam M Z, De Leon I and Boyd R W 2016 Science 352 795 | Large optical nonlinearity of indium tin oxide in its epsilon-near-zero region

| [26] | Elim H I, Ji W and Zhu F 2006 Appl. Phys. B 82 439 | Carrier concentration dependence of optical Kerr nonlinearity in indium tin oxide films

| [27] | Guo J, Zhang H, Li Z, Sheng Y, Guo Q, Han X, Liu Y, Man B, Ning T and Jiang S 2018 Opt. Mater. 78 432 | Dark solitons in erbium-doped fiber lasers based on indium tin oxide as saturable absorbers

| [28] | Yang S, Zhang C, Chang X, Huang J, Yang Z, Yao J, Wang H and Ding G 2019 Ceram. Int. 45 17048 | Effect of heat treatment atmosphere on the piezoresistivity of indium tin oxide ceramic strain sensor

| [29] | Wohlmuth W and Adesida I 2005 Thin Solid Films 479 223 | Properties of R.F. magnetron sputtered cadmium–tin–oxide and indium–tin–oxide thin films

| [30] | Cho H and Yun Y H 2011 Ceram. Int. 37 615 | Characterization of indium tin oxide (ITO) thin films prepared by a sol–gel spin coating process