| CONDENSED MATTER: STRUCTURE, MECHANICAL AND THERMAL PROPERTIES |

|

|

|

|

|

High Mixing Entropy Enhanced Energy States in Metallic Glasses |

| Juntao Huo1, Kangyuan Li2, Bowen Zang1, Meng Gao1, Li-Min Wang3, Baoan Sun4, Maozhi Li2*, Lijian Song1*, Jun-Qiang Wang1*, and Wei-Hua Wang4 |

1CAS Key Laboratory of Magnetic Materials and Devices, and Zhejiang Province Key Laboratory of Magnetic Materials and Application Technology, Ningbo Institute of Materials Technology & Engineering, Chinese Academy of Sciences, Ningbo 315201, China

2Department of Physics, Renmin University of China, Beijing 100872, China

3State Key Lab of Metastable Materials Science and Technology, and College of Materials Science and Engineering, Yanshan University, Qinhuangdao 066004, China

4Institute of Physics, Chinese Academy of Sciences, Beijing 100190, China

|

|

| Cite this article: |

|

Juntao Huo, Kangyuan Li, Bowen Zang et al 2022 Chin. Phys. Lett. 39 046401 |

|

|

|

|

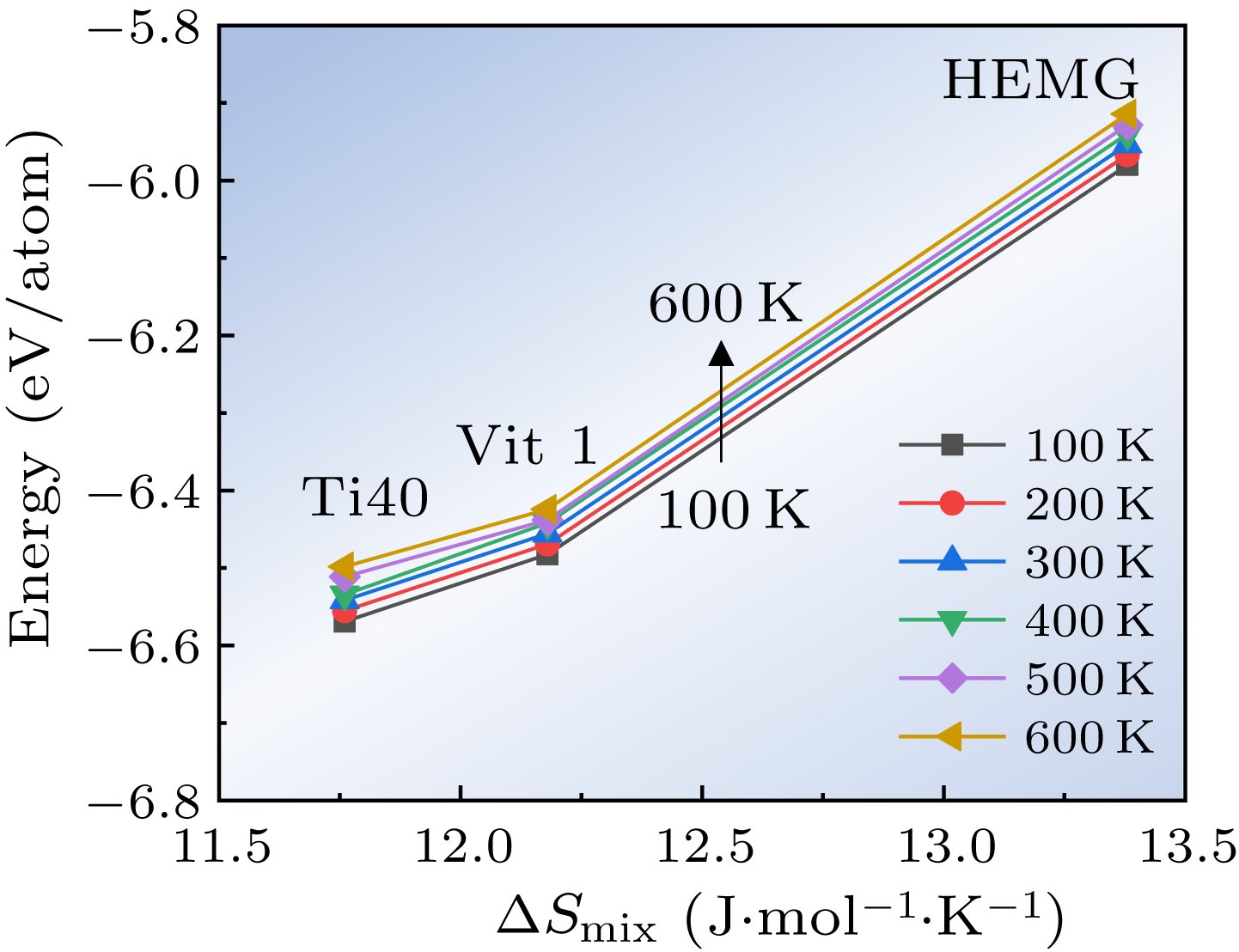

Abstract Owing to the nonequilibrium nature, the energy state of metallic glasses (MGs) can vary a lot and has a critical influence on the physical properties. Exploring new methods to modulate the energy state of glasses and studying its relationship with properties have attracted great interests. Herein, we systematically investigate the energy state, mixing entropy and physical properties of Zr–Ti–Cu–Ni–Be multicomponent high entropy MGs by experiments and simulations. We find that the energy state increases along with the increase of mixing entropy. The yield strength and thermal stability of MGs are also enhanced by high mixing entropy. These results may open a new door on regulation of energy states and thus physical properties of MGs.

|

|

Received: 23 February 2022

Express Letter

Published: 10 March 2022

|

|

| PACS: |

64.70.pe

|

(Metallic glasses)

|

| |

65.60.+a

|

(Thermal properties of amorphous solids and glasses: heat capacity, thermal expansion, etc.)

|

|

|

|

|

|

| [1] | Wang W H 2009 Adv. Mater. 21 4524 |

| [2] | Schroers J 2010 Adv. Mater. 22 1566 |

| [3] | Wang W H, Dong C, and Shek C H 2004 Mater. Sci. Eng. R 44 45 |

| [4] | Wang W H 2012 Prog. Mater. Sci. 57 487 |

| [5] | Li D M, Chen L S, Yu P, Ding D, and Xia L 2020 Chin. Phys. Lett. 37 086401 |

| [6] | Zhang S, Wang W, and Guan P 2021 Chin. Phys. Lett. 38 016802 |

| [7] | Dong J, Feng Y H, Huan Y, Yi J, Wang W H, Bai H Y, and Sun B A 2020 Chin. Phys. Lett. 37 017103 |

| [8] | Wang Y J, Du J P, Shinzato S, Dai L H, and Ogata S 2018 Acta Mater. 157 165 |

| [9] | Sun Y, Concustell A, and Greer A L 2016 Nat. Rev. Mater. 1 16039 |

| [10] | Shen J, Huang Y J, and Sun J F 2007 J. Mater. Res. 22 3067 |

| [11] | Xiao Y, Wu Y, Liu Z, Wu H, and Lue Z 2010 Sci. Chin. Phys. Mech. & Astron. 53 394 |

| [12] | Miyazaki N, Lo Y C, Wakeda M, and Ogata S 2016 Appl. Phys. Lett. 109 091906 |

| [13] | Wang W H 2019 Prog. Mater. Sci. 106 100561 |

| [14] | Ediger M D, Gruebele M, Lubchenko V, and Wolynes P G 2021 J. Phys. Chem. B 125 9052 |

| [15] | Tong X, Zhang Y, Wang Y, Liang X, Zhang K, Zhang F, Cai Y, Ke H, Wang G, Shen J, Makino A, and Wang W 2022 J. Mater. Sci. & Technol. 96 233 |

| [16] | He N, Song L, Xu W, Huo J, Wang J Q, and Li R W 2019 J. Non-Cryst. Solids 509 95 |

| [17] | Pan J and Duan F 2021 Acta Metall. Sin. 57 439 |

| [18] | Jiang S, Huang Y, and Li M 2019 Chin. Phys. B 28 046103 |

| [19] | Qiang J and Tsuchiya K 2017 J. Alloys Compd. 712 250 |

| [20] | Feng S D, Chan K C, Zhao L, Pan S P, Qi L, Wang L M, and Liu R P 2018 Mater. & Des. 158 248 |

| [21] | Guo W, Yamada R, Saida J, Lu S, and Wu S 2018 Nanoscale Res. Lett. 13 398 |

| [22] | Saida J, Yamada R, Wakeda M, and Ogata S 2017 Sci. Technol. Adv. Mater. 18 152 |

| [23] | Miyazaki N, Wakeda M, Wang Y J, and Ogata S 2016 npj Comput. Mater. 2 16013 |

| [24] | Priezjev N V 2019 J. Mater. Res. 34 2664 |

| [25] | Priezjev N V 2019 J. Non-Cryst. Solids 503 131 |

| [26] | Ma Y B, Mei L, Cui X, and Zu F Q 2021 Kovove Mater.-Metallic Mater. 59 181 |

| [27] | Ri M C, Sohrabi S, Ding D W, Dong B S, Zhou S X, and Wang W H 2017 Chin. Phys. B 26 066101 |

| [28] | Afonin G V, Mitrofanov Y P, Kobelev N P, Pinto M W D S, Wilde G, and Khonik V A 2019 Scr. Mater. 166 6 |

| [29] | Wang J G, Yang H, Pan Y, Song Y J, Li W H, and He Y Z 2016 J. Non-Cryst. Solids 452 273 |

| [30] | Guo F Q, Wang H J, Poon S J, and Shiflet G J 2005 Appl. Phys. Lett. 86 091907 |

| [31] | Lu J, Ravichandran G, and Johnson W L 2003 Acta Mater. 51 3429 |

| [32] | Kresse G and Furthmuller J 1996 Phys. Rev. B 54 11169 |

| [33] | Sheng H W, Luo W K, Alamgir F M, Bai J M, and Ma E 2006 Nature 439 419 |

| [34] | Blöchl P E 1994 Phys. Rev. B 50 17953 |

| [35] | Wang Y and Perdew J P 1991 Phys. Rev. B 44 13298 |

| [36] | Pinal R 2008 Entropy 10 207 |

| [37] | Inaba S, Oda S, and Morinaga K 2003 J. Non-Cryst. Solids 325 258 |

| [38] | Ke H B, Wen P, Zhao D Q, and Wang W H 2010 Appl. Phys. Lett. 96 251902 |

| [39] | Höhne G, McNaughton J, Hemminger W, Flammersheim H J, and Flammersheim H J 2003 Differential Scanning Calorimetry 2nd edn (New York: Springer Science & Business Media) p 147 |

|

|

Viewed |

|

|

|

Full text

|

|

|

|

|

Abstract

|

|

|

|

|